| C 0.17-0.22 | Si 0.40 max | MN 1.10-1.40 | S 0.035 max | P 0.035 max | Cr 1.00-1.30 |

Virat Special Steels is the biggest & leading Supplier & Stockiest of 20Mncr5 Steel. 20MnCr5 is used for materials with a required core tensile strength of 1000 – 1300 N/mm² and just right carrying resistance as boxes, piston bolts, spindles, camshafts, gears, shafts and other mechanical controlling materials.

20MnCr5 is used for materials with a required core tensile strength of 1000 – 1300 N/mm² and just right carrying resistance as boxes, piston bolts, spindles, camshafts, gears, shafts and other mechanical controlling materials.

| Thermal Conductivity at °C | 20 | 350 | 700 |

| W/(m*K) | 11.7 | 12.8 | 13.5 |

Alloyed case hardening steel for parts with a required core tensile strength of 1000 – 1300 N/mm² and good wearing resistance as boxes, piston bolts, spindles, camshafts, gears, shafts and other mechanical controlling parts.

| Soft annealing °C | Cooling | Hardness HB |

|---|---|---|

| 750-780 | Furnace | max. 218 |

| Stress-relief annealing °C | Cooling |

|---|---|

| 550-600 | Furnace |

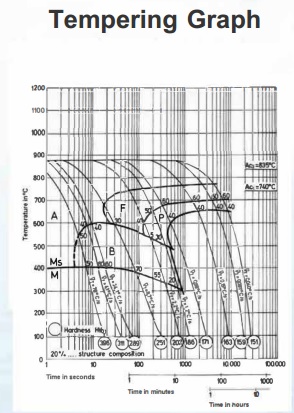

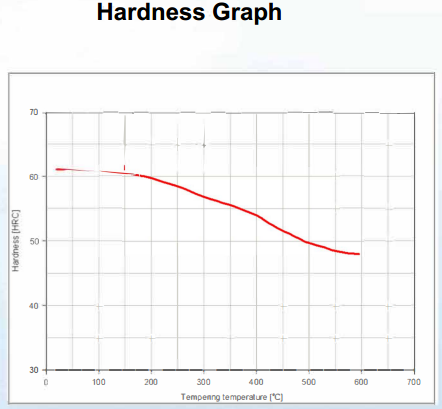

| 1st pre-heating °C | 2nd and 3rd | Hardening °C | Quenching | Tempering °C | Hardness after Teperature HRC |

|---|---|---|---|---|---|

| up to approx. 400 in an air-circulating furnace | 740 and 840 | 780-820 | 810 °C Oil ,Quench | at least twice 150-200 | 60 – 62 |