| C | Si | Mn | P | S | Cr | Mo | Ni |

|---|---|---|---|---|---|---|---|

| 0.35 - 0.45 | 0.20 - 0.40 | 0.60 - 1.00 | 0.03 | 0.03 | 1.80 - 2.10 | 0.15 - 0.25 | 0.90 - 1.20 |

DIN 1.2738 is specially used for Plastic injection die moulds. The characteristics of a material are right sharpening, photo-etching properties with high purity and good homogeneity. DIN 2738 is upgraded version of plastic mold steel 0f 2311, which normally supply in Pre hardened condition. Hardness in as supplied condition 280-320 HB with having uniform hardness. The additional nickel content of 1 % increases through hardening. It has good machinability, suitable for Texturing, fine polishability, adequate corrosion resistance, vacuum-degassed steel.

The modified version of 2738 is with High Hardness 360-400 BHN and increase alloy elements to get extra life and outstanding polishing.

DIN 2738 steel is a type of plastic mold steel that is similar to P20+Ni /AISI P20+Ni Tool Steel. The alloying elements for hardness and toughness include nickel, chromium, and molybdenum. DIN 2738 tool steel is intended specifically for the plastic mold industry, particularly for large steel mold components. DIN 2738 tool steel is often provided pre-hardened/quenched and tempered in the 280 - 320 HB hardness range. This makes it a great choice for applications involving high-temperature settings and difficult mechanical conditions.

DIN 2738 steels have superior polishability compared to 1.2312 (AISI P20+S) and better machinability. To enhance the hardness and wearability of the mould surface material , it can be treated with nitrogenation and flame hardening. DIN 2738 steel is melted in an electrical furnace and refined using a VOD or DH equipment.

Virat Special Steels is the largest stockiest and supplier of DIN 2738 Steel in flat, square and round bar. We provide steel in all sizes as your requirements. DIN 2738 die steel is available in flat, square and round shape. Consult our team who will assist you for DIN 2738 steel query.

DIN 2738 is upgrade version of plastic mold steel 0f 2311, which normally supply in Pre hardened condition. Hardness in as supplied condition 280-320 HB. The additional nickel content of 1 % increases through hardening. It is micro-alloyed. It has good machinability, suitable for texturing, outstanding polishability, adequate corrosion resistance. vacuum-degassed steel with the following excellent features.

| Tensile Strength | 850 MPa-1100MPa |

| Yield Strength | 770-980 MPa |

| Hardness | 235 HB |

| Elongation | 13%-16% |

| Impact Toughness | 20 J/cm2-42 J/cm2 |

| Modulus of elasticity | 205 x 10³N/mm2 |

The physical properties can vary slightly depending on the specific composition and heat treatment of the P20+Ni /DIN 2738 /AISI P20+Ni steel. It's always recommended to refer to the manufacturer’s specifications for precise information.

| Coefficient of thermal expansionat °C | 20-100 | 20-200 | 20-300 | 20-400 | 20-500 | 20-600 | 20-700 |

| 10-6 m/(m*K) | 11.2 | 12.8 | 13.5 | 13.7 | 14.3 | 14.7 | 14.9 |

| Thermal Conductivity at °C | 20 | 350 | 700 |

| W/(m*K) | 35 | 34 | 33 |

P20+Ni / DIN 2738 / AISI P20+Ni is already pre-toughened, thus no heat treatment is necessary if no particular needs exist.

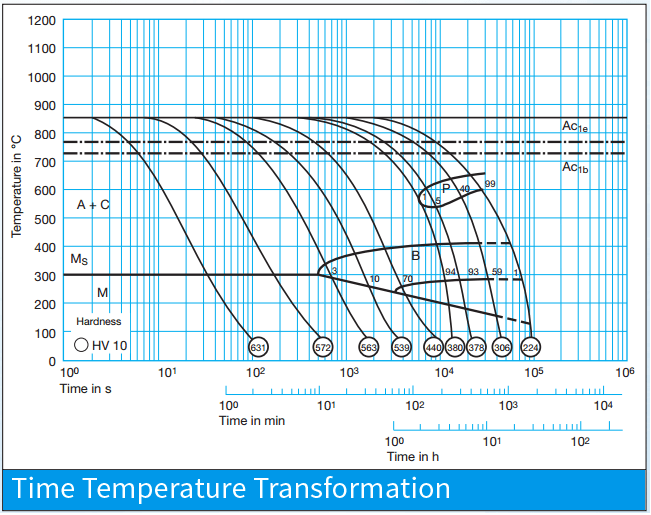

Harden from 840-870°C, followed by oil, and finally quench in oil/hot bath/air 180-220 °C. The hardness after quenching is approximately 52 HRC.

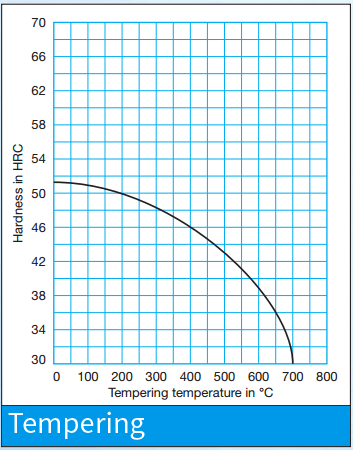

After hardening, slowly heat the part to the tempering temperature; the minimum duration in the furnace is one hour for every 20 mm of part thickness; two tempering is advised.

1093-898 °C.

Approx. 650°C.

Approx 900°C

The maximum Brinell hardness will be 235 after being heated to 710 to 740 °C for 2 to 5 hours, and then gently cooled to 600 °C additional cooling in air.

For the welding process , P20+Ni tool steel conventional methods are used.

840-870 °C.

| Soft annealing °C | Cooling | Hardness HB |

|---|---|---|

| 710 – 740 | Furnace | max. 235 |

| Hardening °C | Quenching | Hardness after quenching HRC |

|---|---|---|

| 840 – 870 | Polymer or oil | 51 |

| Tempering °C after Quenching | 100 | 200 | 300 | 400 | 500 | 600 | 700 |

| HRC | 51.5 | 50.2 | 48 | 46.2 | 43 | 39 | 29 |

DIN 2738 is applicable for large & small plastic mould dies for Automotive Industries, Dies for Domestic goods , High finishing plastic Die, Boaster Plates of Presses, Die Holders & Shoe blocks for drop Hammers, Press Cassettes , Upsetter Blocker, forging dies, Different dies & mold for plastic products etc.