| C | Si | Mn | P | S | Cr | Mo | V |

|---|---|---|---|---|---|---|---|

| 0.32-0.45 | 0.80-1.25 | 0.20-0.60 | 0.03 | 0.03 | 4.75-5.50 | 1.10-1.75 | 0.80-1.20 |

AISI-H13 tool steel is the most popular steel grade for various Industries. The main features of high alloyed Cr-Mo-V Hot Work tool steel is high wear resistance to thermal shock and to heat cracking, good mechanical characteristics & toughness in hot condition. AISI H13 appears excellent machinability with constant hardness during production activities. The equivalent steel grade H13 / SKD61 / AISI H13 normally available in the annealed condition but in some specific applications, we provide Pre-Hard AISI H13 with its standard hardness 460-500 BHN. Utilized for ejector pins, apparatus holders and shrink fit chucks.

AISI H13 tool steel is a widely used hot work tool steel that belongs to the AISI (American Iron and Steel Institute) H-series steels. It is renowned for its exceptional combination of high hardness, toughness, and heat resistance, making it well-suited for a variety of applications in hot work tooling. AISI H13 tool steel contains a composition of approximately 1.4% to 1.6% carbon, 4.75% to 5.5% chromium, 0.3% to 1% molybdenum, 1% vanadium, and smaller amounts of other alloying elements such as silicon and manganese. This specific composition contributes to its excellent properties, including high hardness, good abrasion resistance, high toughness, ductility, machinability , polishability, good high-temperature strength and resistance to thermal fatigue, very limited distortion during hardening.

Vanadium and molybdenum serve as strengthening elements in steel AISI H13. Die steel AISI H13's high chromium content helps it resist softening when utilized at high temperatures. AISI H13 die steels have good red hardness and a great mix of stress and abrasion resistance. It can endure quick cooling and withstands early heat testing. It is frequently used in hot and cold work tooling applications due to its extraordinary combination of heat resistance, hardness, and toughness. This makes it a great choice for applications involving high-temperature settings and difficult mechanical conditions.

Virat Special Steels is the largest stockiest and supplier of AISI H13 tool steel in flat, square and round bar. We provide steel in all sizes as your requirements. AISI H13 die steel is available in flat, square and round shape. Consult our team who will assist you for AISI H13 steel query.

ESR is the most refined material with the traditional VD route. The quality of material increase the toughness, highly increase the micro- cleanness level.

Highly recommend the use of AISI-H13 ESR grade for Aluminum Pressure Die Casting & other component subjected to high working temperatures and high pressure strength. DIN 2344 is fully ultrasonic inspected with 100% positive results as per NDT standards.

High hot-wear resistance and hot tensile strength as well as good toughness, thermal conductivity and insusceptibility to hotcracking. Can be water-cooled to a limited extent.

| Tensile strength | 1550 MPa-2050MPa |

| Yield Strength | 1000-1380 MPa |

| Elongation | 10%-15% |

| Impact Toughness | 20 J/cm2-40 J/cm2 |

| Hardness | 45-52 HRC |

| Compressive Strength | 2550MPa |

| Modulus of elasticity | 215 GPa |

Depending on the precise composition and heat treatment of the H13 steel, the physical attributes may differ somewhat. It's always advisable to refer to the manufacturer’s specifications for accurate information.

| Coefficient of thermal expansionat °C | 20-100 | 20-210 | 20-300 | 20-400 | 20-500 | 20-600 | 20-700 |

| 10-4 m/(m*K) | 10.8 | 12 | 12.4 | 12.7 | 13.1 | 13.3 | 13.5 |

| Thermal Conductivity °C | 20 | 350 | 700 |

| W/(m*K)Annealed | 27.1 | 30.4 | 33.2 |

| W/(m*K)Quenched & Tempered | 25.4 | 27.7 | 30.4 |

AISI-H13 has a medium to good machinability. It rates as 75% that of the low alloy, typically well-machinable W group water hardening tool steels.

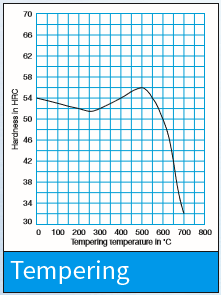

Hardness tests were conducted on 1-inch-round AISI-H13 specimens that had been air-quenched at 1850°F and subjected to two hours of tempered heating and cooling.

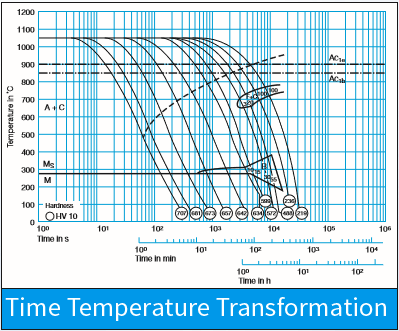

Preheating AISI-H13 tool steels to 816°C (1500°F). The temperature is then instantly raised to 1010°C (1850°F) and held there for 15 to 40 minutes before being applied to the steels. After that, the steels are air-quenched.

AISI-H13 tool steel should be hardened by cooling in still air since it has a very high degree of hardenability. If a salt bath or controlled environment furnace is not available, pack hardening in wasted pitch coke is advised to reduce decarburization. The temperature used ranges from 1800° to 1850°F, depending on the size of the part.

Heat must be applied evenly and gently for forging. Reheat as often as necessary while soaking through at 1900°–2000°F; cease working when the temperature falls below 1650°F. After forging, cool gradually in a furnace, lime, mica, or dry ashes. After forging, AISI-H13 should always be annealed.

After machining, welding, or other high-temperature procedures on AISI-H13 steel, stress relieving is a heat treatment procedure used to lower internal tensions and enhance dimensional stability.

Do Not Normalize.

AISI-H13 tool steels are annealed in the furnace at 871°C (1600°F) and then slowly chilled at 4°C (40°F).

Cold working may be carried out on AISI-H13 tool steels using conventional methods.

Nitriding is used to give AISI-H13 tool steel a hard surface covering. The steel has a strong resistance to corrosion and abrasion as a result. Nitriding also increases corrosion resistance. Nitriding in ammonia gas at a temperature of 525°C results in surfaces with surface hardness ranging from 1000 to 1250 HV. Before being nitrided, the tool has to be hardened and tempered to a temperature that is around 50°C higher than the nitriding temperature.

AISI-H13 tool steels may easily be joined together using a variety of welding techniques, such as gas tungsten arc welding, shielded metal arc welding, and gas metal arc welding.

Using a quenching medium such as air, oil, water, or polymer solutions, the AISI-H13 steel is quickly cooled to room temperature or lower. The target hardness, distortion control, and component shape are only a few examples of the variables that affect the quenching medium selection. The temperature range required for quenching steel is (500-550 °C).

Quenching leaves the steel with an extremely rigid yet fragile structure. Immediately following quenching, the hardened AISI-H13 steel is commonly tempered in order to increase toughness and relieve internal tensions. Reheating the steel to a certain temperature range—typically between 500°C and 650°C (1202°F)—and maintaining it there for a predetermined amount of time is known as tempering. In fact, this procedure aids in lowering the steel's hardness, boosting its toughness, and improving its overall performance. A hardness of 53 to 38 HRC is achieved by tempering AISI-H13 tool steels between 538 and 649°C (1000 and 1200°F). These steels can also undergo double tempering once per hour at the chosen tempering temperature.

| Soft annealing °C | Cooling | Hardness HB |

|---|---|---|

| 760 - 810 | Furnace | max. 240 |

| Stress-relief annealing °C | Cooling |

|---|---|

| approx. 610 - 660 | Furnace |

| Hardening °C | Quenching | Hardness after quenching HRC |

|---|---|---|

| 1030 - 1060 | Air ,oil or saltbath, 500 - 550 °C | 55 |

| Tempering °C | 100 | 210 | 300 | 400 | 500 | 550 | 600 | 650 | 700 |

| HRC | 54 | 53 | 53 | 55 | 56 | 54 | 51 | 43 | 34 |

Dies for Drop Forgings , Aluminum / low Pressure Die Casting, Extrusion Dies, Gripper Dies, Moulds/Die For Street Light, Metal Track Pressure Tools, Forging Dies, Containers & liner, Punches, Plugs, Holdez, Injection moulds , Aluminium Extrusions Die Steel , Etc.